Courtesy: National Energy Technology laboratory, USA.

Courtesy: Polk Power Station, Integrated Coal Gasification Combined cycle (ICGC) plant,Florida, USA

Courtesy: https://pib.gov.in/

Courtesy: https://pib.gov.in/

BHEL and Coal India Joint Venture to Produce Around 2000T of Ammonium Nitrate per Day using Surface Coal Gasification Technology

Team Chemical Market

04 Mar 2024

A news item that have caught considerable interest recently was concerning two prominent public sector entities in India, Bharat Heavy Electricals Limited(BHEL) and Coal India Ltd (CIL). They cemented a joint venture agreement (JVA), launching a significant collaboration. The agreement outlines plan for the joint production of 2000 Tons Per Day (TPD) or 6.6 lakh tons annually of Ammonium Nitrate. Coal being designated as the primary raw material; synthesis of the end product will require 1.3 MT (Million Tons) annually. The proposed plant is planned to be established at Lakhanpur, Odisha, India, in the vicinity of Mahanadi Coalfields. The financial backing has been secured from the Govt of India. At its core, this Surface Coal Gasification plant (SCG), will use BHEL's indigenous Pressurized Fluidised Bed Gasification(PFBG) technology. Ammonium Nitrate being predominantly sourced from Russia, Germany, and Bulgaria, is significant, with 46,000 Tons imported in September 2023. In resonance with the Govt of India's initiative of Atmanirbhar Bharat Abhiyan (self-reliant economy), this endeavor primarily aims to mitigate dependence on imports. Notably, the primary consumers of Ammonium Nitrate are industries engaged in the manufacturing of explosives, which find extensive use in open-cast mining. Much of the coal mined in India has a high ash content.

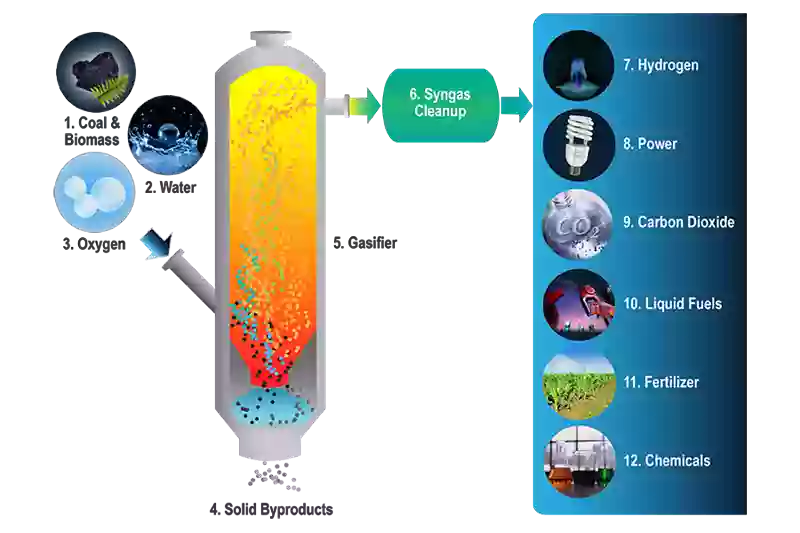

In a conventional boiler, coal is burnt in the presence of excess air, resulting in the process of oxidation. The heat produced is used to raise steam, for use in further processes. The combustion emits SOX and NOX in the form of flue gas, which are harmful to the environment. Now, please refer to the figure above. In PBFG, a reduction process occurs, which is the fundamental difference. Oxygen levels are much lower than that required for oxidation. The reaction of high Ash content coal, water, and oxygen under a pressure of about 30 Kg/ cm2 and a temperature of 800 to 1050 deg C in the reactor, yields Syngas, which is predominantly composed of Hydrogen. The high-pressure operation results in a low level of impurities like Sulphur dioxide and Carbon dioxide. These are easily removed in the Syngas cleanup. Processes such as Haber - Bosch and Ostwald are used to make Ammonia and Nitric acid from Hydrogen. Nitric acid is then combined with Ammonia to yield liquid Ammonium Nitrate. The resulting product is solidified and turned into granules through prilling and granulation. The actual process adopted in the project may vary from the method described, as it is dependent on various parameters. As shown in the figure, Syngas is a versatile source for numerous applications. The major challenge in the project is the use of high-ash-content coal. Safe handling of Ammonium Nitrate (explosive)and corrosive agents, safe disposal of wastes are critical concerns. Hydrogen with a high calorific value, when oxidized yields energy and water. It is thus classified as a clean fuel, having little or no detrimental effect on the environment.

The National Coal Gasification Mission, with its ambitious target of 100 Million Tons by 2030, reflects a strategic shift towards cleaner energy production. Concurrently, India's pledge to the Paris Accord of 2015 to gradually reduce CO2 emissions demonstrates a commitment to global climate action. The transition towards a clean energy economy, particularly emphasizing hydrogen-based technologies, indicates a progressive approach to mitigating environmental impacts. As aspirations towards achieving carbon-neutral status by 2070 are articulated, there emerges a collective determination to pave the way for a healthier planet for future generations. Against this backdrop, entities such as CIL and BHEL stand as pivotal players in India's industrial landscape, exemplifying expertise and innovation in their respective domains. CIL's operations encompass vital aspects of coal extraction and supply, catering to diverse sectors including thermal power, steel, and cement industries. Meanwhile, BHEL boasts a rich legacy spanning over five decades, contributing significantly to India's evolution. With strong capabilities in research, engineering, manufacturing, and construction, BHEL stands poised to play a substantial role in India's resurgence, driving innovation and progress across diverse sectors, thereby underpinning the the nation's odyssey toward sustainable advancement.

References: https://pib.gov.in/PressReleaseIframePage.aspx?PRID=2009826